What is the ARMS?

The AXIS ALIGNMENT is a very important function that should be used when you intend to cut pre-printed media, such as stickers or decals.

The AXIS ALIGNMENT function enables to electrically adjust the contour cutting data to align with the printed image using reference marks.

ARMS is an abbreviation for Advanced Registration Mark Sensing system, which uses sensors to detect registration marks and performs the AXIS ALIGNMENT. It is installed in recent cutting plotter of the Graphtec.

It enables to significantly improve productivity in the Print & Cut applications that makes stickers or decals.

What is the registration mark?

The registration marks is a reference mark for the AXIS ALIGNMENT that makes precisely aligning the actual cutting line with the printed image on media. It is necessary that marks specified by GRAPTEC are printed on the media to use the ARMS.

Available functions by model of cutting plotter

Function of ARMS varies by model and its condition. Please refer to the following list.

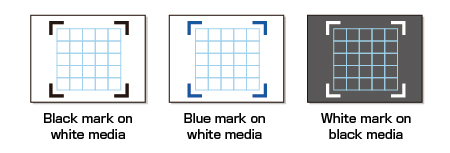

1. Auto sensitivity adjust (Mark may not be detected due to poor printing quality or media surface.)

The sensitivity of the registration mark sensor is automatically set by measuring the reflective level of the marks of the actual media. The mark can be detected when the color of the mark has a reasonable contrast against the background. For example, a white mark can be detected on a colored background.

The sensitivity of the registration mark sensor is automatically set by measuring the reflective level of the marks of the actual media. The mark can be detected when the color of the mark has a reasonable contrast against the background. For example, a white mark can be detected on a colored background.

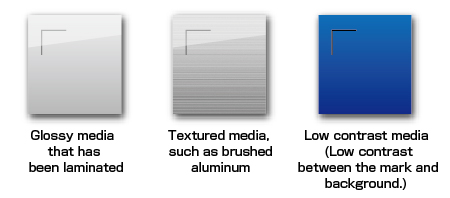

2. ISM (Intelligent Scan Mode) (Mark may not be detected due to poor printing quality or media surface.)

ISM incorporates a new scanning algorithm that expands the range of compatible media. ISM increases the mark scanning success, and can also detect the registration mark on textured media, such as brushed aluminum, or glossy laminated materials.

ISM incorporates a new scanning algorithm that expands the range of compatible media. ISM increases the mark scanning success, and can also detect the registration mark on textured media, such as brushed aluminum, or glossy laminated materials.

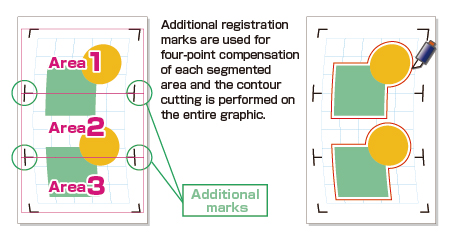

3. Segment area compensation

The 4-point axis alignment is performed for each segmented area. This is performed by reading the mark in the middle of the feeding direction for entire graphic and then cutting the entire graphic, provides high-precision alignment for long length Print & Cut applications. The cutting plotter can be configured to this condition using Graphtec software. XY segment area compensation is avairable only for FC9000 series.

The 4-point axis alignment is performed for each segmented area. This is performed by reading the mark in the middle of the feeding direction for entire graphic and then cutting the entire graphic, provides high-precision alignment for long length Print & Cut applications. The cutting plotter can be configured to this condition using Graphtec software. XY segment area compensation is avairable only for FC9000 series.

Supporting software: Cutting Master 4, Cutting Master 3 , Graphtec Pro Studio / Graphtec Pro Studio Plus, GRAPHTEC STUDIO , Plotter Controller

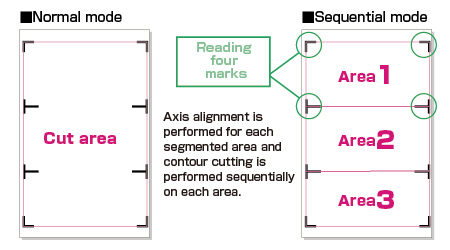

4. Segment area compensation (sequential mode)

The 4-point axis alignment is performed for each segmented area. This is performed by reading the mark in the middle of the feeding direction and then contour cutting is performed sequentially in each segmented area. Media movement is limited to the smaller area being cut, improving accuracy and tracking for heavier media or media that is the entire graphic, provides high-precision alignment for long length Print & Cut applications. The cutting plotter can be configured to this condition using Graphtec software

The 4-point axis alignment is performed for each segmented area. This is performed by reading the mark in the middle of the feeding direction and then contour cutting is performed sequentially in each segmented area. Media movement is limited to the smaller area being cut, improving accuracy and tracking for heavier media or media that is the entire graphic, provides high-precision alignment for long length Print & Cut applications. The cutting plotter can be configured to this condition using Graphtec software

Supporting software: Cutting Master 4, Cutting Master 3 , Graphtec Pro Studio / Graphtec Pro Studio Plus, GRAPHTEC STUDIO

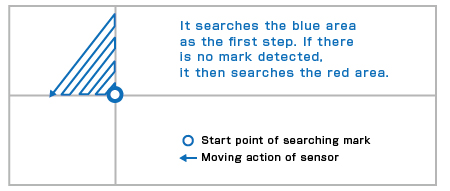

5. Auto mark detection (ver.1)

The first registration mark is automatically detected within search area; this eliminates the need to manually move the sensor near the registration mark position. It improves the operation of the registration mark searching.

The first registration mark is automatically detected within search area; this eliminates the need to manually move the sensor near the registration mark position. It improves the operation of the registration mark searching.

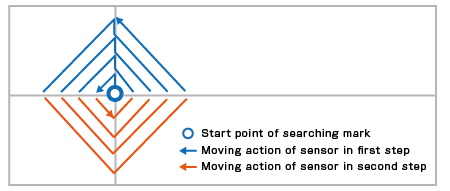

6. Auto mark detection (ver.2)

The first registration mark is automatically detected within a wide search area including the negative area from the starting point; this eliminates the need to manually move the sensor near the registration mark position. It improves the operation of the registration mark searching.

The first registration mark is automatically detected within a wide search area including the negative area from the starting point; this eliminates the need to manually move the sensor near the registration mark position. It improves the operation of the registration mark searching.

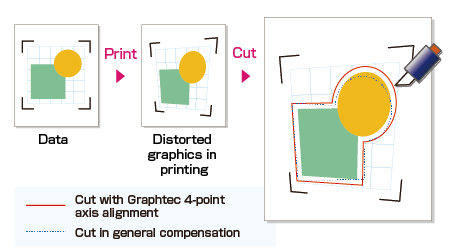

7. 4-point axis alignment

This feature compensates for any distortion in printed graphics to ensure precise contour cutting. The axis alignment using 2-point and 3-point that are faster with limited compensation are also available.

This feature compensates for any distortion in printed graphics to ensure precise contour cutting. The axis alignment using 2-point and 3-point that are faster with limited compensation are also available.

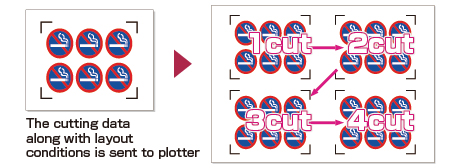

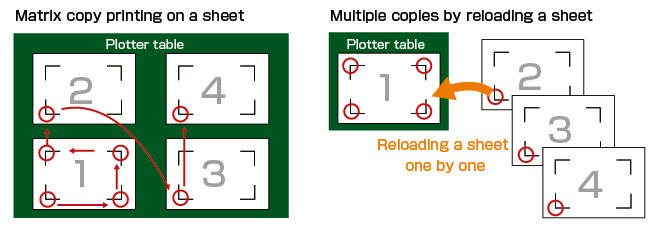

8. Multiple-mark compensation

When the design is printed with the matrix copy condition using RIP software, the action of reading the mark and contour cutting is repeated for each copy. It significantly improve productivity for Print & Cut applications. The cutting plotter can be configured to this condition using Graphtec software.

When the design is printed with the matrix copy condition using RIP software, the action of reading the mark and contour cutting is repeated for each copy. It significantly improve productivity for Print & Cut applications. The cutting plotter can be configured to this condition using Graphtec software.

Supporting software: Cutting Master 4, Cutting Master 3 , Graphtec Pro Studio / Graphtec Pro Studio Plus, GRAPHTEC STUDIO

9. Supports ARMS control commands

The special command for controlling the registration mark sensing system (ARMS) is supported. The setting parameter for ARMS can be set from the PC using the software.

Supporting software: Cutting Master 4, Cutting Master 3 , Graphtec Pro Studio / Graphtec Pro Studio Plus, GRAPHTEC STUDIO , Plotter Controller

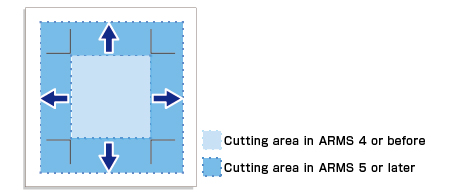

10. Expanded effective cutting area

In case of ARMS 4 or before, the cutting area is up to the area enclosed by the registration mark. In case of ARMS 5 or later, the cutting area is expanded to outside of the area enclosed by the registration mark. This increases the production efficiency by reducing media waste.

In case of ARMS 4 or before, the cutting area is up to the area enclosed by the registration mark. In case of ARMS 5 or later, the cutting area is expanded to outside of the area enclosed by the registration mark. This increases the production efficiency by reducing media waste.

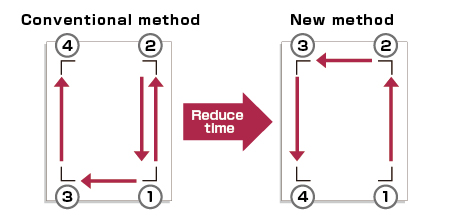

11. Reduce mark detection time

Sequence of scanning the mark is changed for significantly reducing the mark detection time. This function is available in ARMS 5.0 or later.

Sequence of scanning the mark is changed for significantly reducing the mark detection time. This function is available in ARMS 5.0 or later.

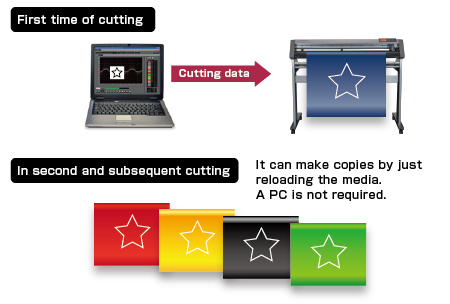

12. ARMS Copy

After data is sent the first time, it can be copied multiple times without a PC. It enables to improve the work efficiency of Print & Cut applications.

After data is sent the first time, it can be copied multiple times without a PC. It enables to improve the work efficiency of Print & Cut applications.

13. Axis alignment by the first mark

After data is sent the first time, it can be copied multiple times without a PC.

In case of ARMS 6.0 that is available on FCX2000 / FCX4000, the first four marks are scanned on the first sheet, and only the first mark in subsequent sheets. This improves productivity by shortening scan detection time. The cutting plotter can be configured to this condition using Graphtec software.

Supporting software: Cutting Master 4, Graphtec Pro Studio / Graphtec Pro Studio Plus

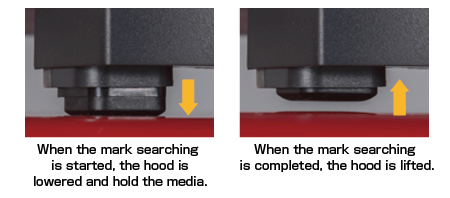

14. Hood of sensor (media holder)

The hood incorporates to the mark sensor part. It has a function of holding the media to the panel for preventing the lifting of the media. It also prevents the influence of ambient light. It can read the mark in stable.

The hood incorporates to the mark sensor part. It has a function of holding the media to the panel for preventing the lifting of the media. It also prevents the influence of ambient light. It can read the mark in stable.

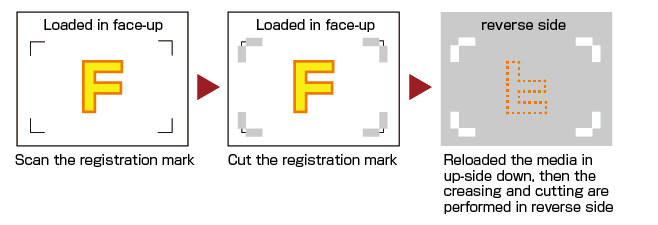

15. Reverse side processing by using ARMS

Cutting and creasing of printed graphics is possible even on the reverse side of the media. This prevents any scratches or damage to the printed graphic. In case of ARMS 6.0 that is available on FCX2000 / FCX4000, operation is very simple when Graphtec software is used.

Supporting software: Cutting Master 4, Graphtec Pro Studio / Graphtec Pro Studio Plus

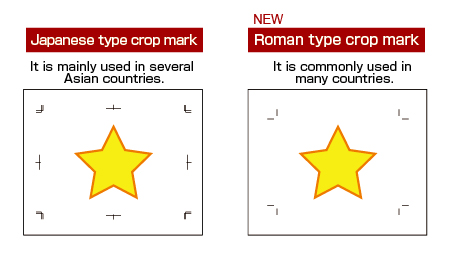

16. Supported the standard crop marks

The axis alignment can be performed using by printed industry standard crop mark for shear. Adding special marks with Graphtec software is not necessary. The Japanese type is supported on the FC2250 series, FCX2000 series and FCX4000 series. The FCX2000 / FCX4000 supports also the Roman type. In case of ARMS 6.0 that is available on FCX2000 / FCX4000, operation is very simple when crop mark information is entered within Cutting Master 4 software when it is used with Adobe Illustrator.

The axis alignment can be performed using by printed industry standard crop mark for shear. Adding special marks with Graphtec software is not necessary. The Japanese type is supported on the FC2250 series, FCX2000 series and FCX4000 series. The FCX2000 / FCX4000 supports also the Roman type. In case of ARMS 6.0 that is available on FCX2000 / FCX4000, operation is very simple when crop mark information is entered within Cutting Master 4 software when it is used with Adobe Illustrator.

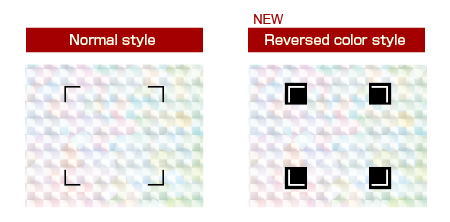

17. Supported reversed color mark

The sensitivity of the registration mark sensor is automatically set by measuring the reflective level of the actual media. The mark can be detected when the color of mark has a reasonable contrast against the background. For example, the mark can be detected with a white mark on a colored background, on a textured media such as brushed aluminum, or on a glossy laminated media.In case of using the Graphtec software, reversed color mark can be easily created.

The sensitivity of the registration mark sensor is automatically set by measuring the reflective level of the actual media. The mark can be detected when the color of mark has a reasonable contrast against the background. For example, the mark can be detected with a white mark on a colored background, on a textured media such as brushed aluminum, or on a glossy laminated media.In case of using the Graphtec software, reversed color mark can be easily created.

Supporting software: Cutting Master 4, Graphtec Pro Studio / Graphtec Pro Studio Plus

18. Supports colored marks / specialty media

A wide variety of media types including holographic paper and reflective sheets are now compatible due to improvements of the ARMS sensor algorithm.

A wide variety of media types including holographic paper and reflective sheets are now compatible due to improvements of the ARMS sensor algorithm.

* Sensor may not be able to read certain combinations of specialty media and colored marks.

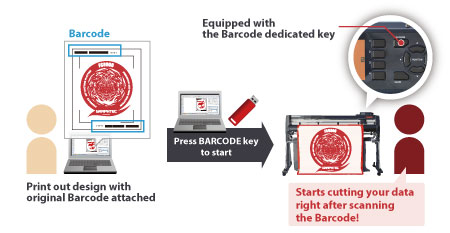

19. Data Link Function (Barcode Data Management/Continuous Cutting)

By reading the Graphtec original Barcode, FC9000/CE7000 automatically detects its linked data from PC or USB flash memory. This function is available regardless of which printer or RIP software is used.

By reading the Graphtec original Barcode, FC9000/CE7000 automatically detects its linked data from PC or USB flash memory. This function is available regardless of which printer or RIP software is used.

* The USB flash memory format only supports FAT32.

Please note that NTFS and exFAT are not supported.

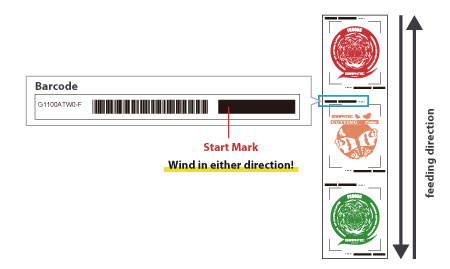

20. Continuous Cut (Data Link function)

Barcode data management allows cutting different data sequentially by detecting the "Start Mark" of the new Barcode. Sequential Print & Cut process with roll-media is now available

Barcode data management allows cutting different data sequentially by detecting the "Start Mark" of the new Barcode. Sequential Print & Cut process with roll-media is now available

{slider Grit rolling type}