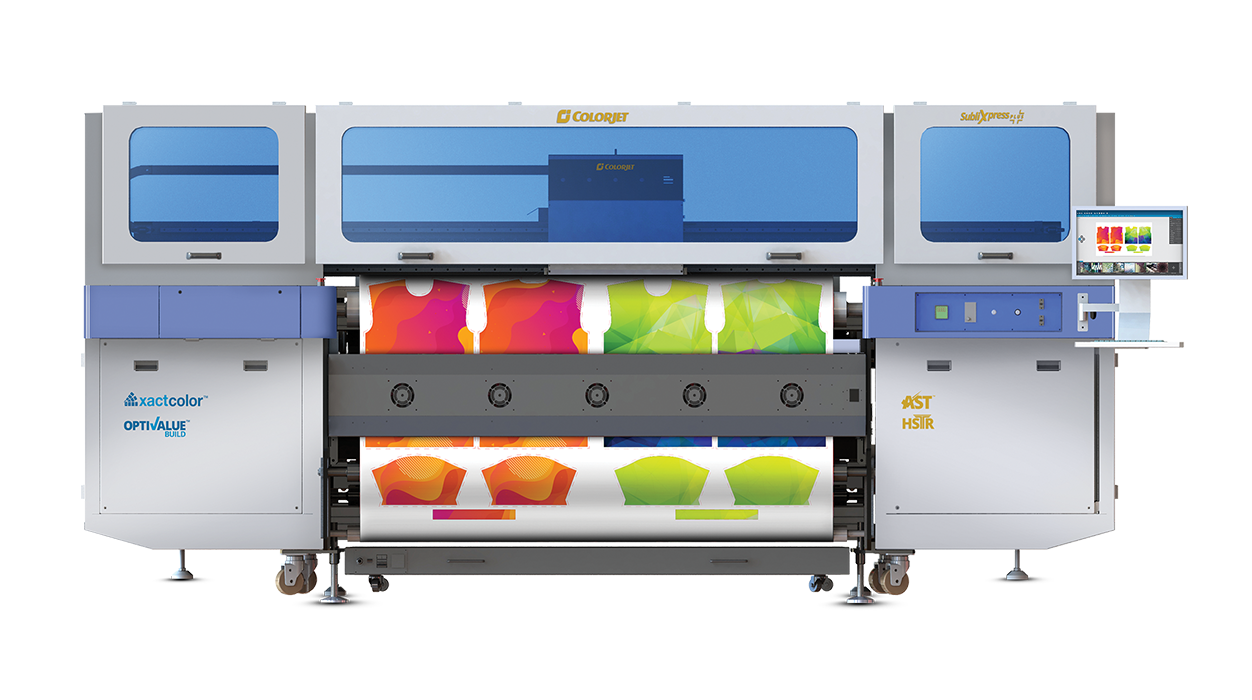

COLORJET LAUNCHES SubliXpress Plus – 9000 Metres/day INDUSTRIAL HEAT TRANSFER PRINTER SERIES

Following the success of the SubliXpress thermal transfer printer series, ColorJet India Ltd has developed for thermal transfer printing at a new level.

Thermal transfer printing is dominating the digital printing sector, accounting for nearly 50% in the garment industry. The thermal transfer printing market, valued at $8.1 billion in 2019, is reaching a CAGR of 10.7% in the forecast period of 2020-2025 and is expected to reach a value of $14.2 billion by 2025. Considering the need for Thermal Transfer Printers to serve the growing apparel market, ColorJet has launched the SubliXpress Plus series of thermal transfer printers.

SubliXpress Plus comes with 8 print heads kyocera so that they can be printed for sizes of ink droplets from 5.7 and 12 pL on request to produce sharp and smooth prints. SubliXpress Plus gives high-speed printing performance but the minimum ink consumption, which is the result of decades of research in the production of digital inkjet printers. ColorJet™ and HSTR™ exclusive development technology is built into the machine to optimize printing capabilities.

ColorJet SubliXpress Plus has a priority position in large-format heat transfer printers, which already have investors looking to own to enhance the value of their business. ColorJet India Ltd also anticipates the explosive growth potential of thermal transfer printing, so there are additions in the technology system to print well on polyester, knitted and woven fabrics.

Despite the negative impact of the pandemic, ColorJet continues to work, produce and develop the next breakthrough technology for the heat transfer printing market.

Advanced technology suitable for all types of paper

With a print width of 1.8 m, the machine can handle a variety of paper from 18 gsm or more.

Leaf Clamping is another great adapt to prevent paper from bending at the edges when printing. Being able to use low gsm paper and the ability to print on smaller scrolls easily, it solves some of the big practical concerns of stores. The vacuum platform holds the paper in a wider spot and the suction pressure is changeable.

A two-stage drying system is provided immediately after the printing area so that the paper does not paste even when printing large patches of color.

HSTR™ (High Sense Paper Tension Regulator) detects the oscillity of paper tension and adjusts it almost immediately to ensure printing is error-free.

Increased machine uptime, uninterrupted production

The printer includes features to enhance productivity including a 900 mm diameter feed roll, a high-precision servo motor, and a large rubber roller with a pneumatic shaft to hold the paper roll core tightly. The machine is also equipped with multiple brush rollers to continuously flatten the paper as it moves from the feed roll to the exhaust roll of the printed paper.

Premium print quality

The new SubliXpress Plus is equipped with a gold-plated metal encodeor for more accurate ink spraying at high speeds, extending its service life. In addition, AST™ (Active Seaming Technology) technology is used to create superior print quality at high speeds.

In summary, SubliXpress Plus is a high quality thermal transfer printing solution, efficiently produced to with low printing costs.