Main Features

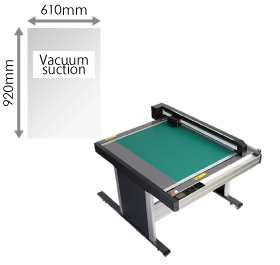

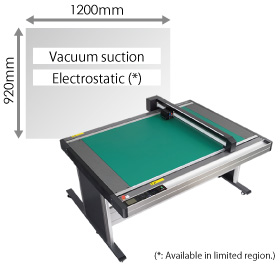

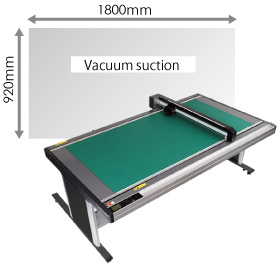

Table size and Media hold-down method

Table size in the Line-up

3 different table size with choice of vacuum suction or

electrostatic media-hold down methods depending on application.

FCX2000-60 (VC)

FCX2000-120 (VC / ES)

FCX2000-180 (VC)

Media hold-down method

Vacuum suction

Holds media using external pump (blower). This method is suitable for heavy or thicker materials.

Electrostatic (*)

Holds media by electrostatic that is generated by electrodes arranged inside the panel. This method is suitable for cutting light weight materials.

(*) Available in limited region.

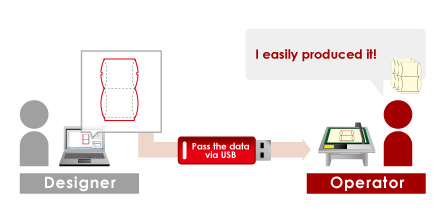

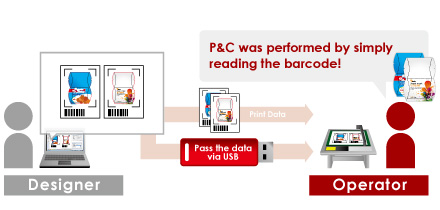

Offline Operation

Offline operation supported by use of USB flash memory

Plot data is created from the design by using Cutting Master 4 or Graphtec Pro Studio, then

the data is saved to USB flash memory. The plot data file can be selected from the USB by menu operation on the plotter, then cutting is performed. This simplified work-flow enables users to operate without a computer.

Supported software : Cutting Master 4 / Graphtec Pro Studio / Graphtec Pro Studio Plus

Data management using bar-code function with USB flash memory

In Print & Cut (referred to as "P&C") operation, the cutting data is automatically selected from USB flash memory by scanning the barcode printed on the media then performs contour cutting. This prevents the usage of incorrect data, and improves work efficiency.

Supported software : Cutting Master 4 / Graphtec Pro Studio / Graphtec Pro Studio Plus

ARMS

Enhanced ARMS (Advanced Registration Mark Sensing system) for improved productivity of P&C applications

Equipped the ARMS (Advanced Registration Mark Sensing system)6.0.

Easy and accurate cutting of pre-printed images using the cutting master 4 and etc.

Enables higher productivity of POP, stickers, and prototype cartons.

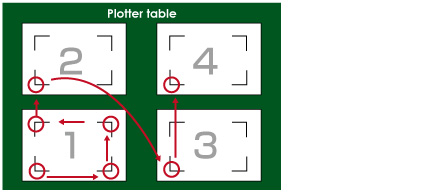

ARMS Copy function

After data is sent the first time, it can be copied multiple times without a PC. In the FCX2000 Series, the first four marks are scanned on the first sheet, and only the first mark in subsequent sheets. This improves productivity by shortening scan detection time.

Matrix copy printing on a sheet

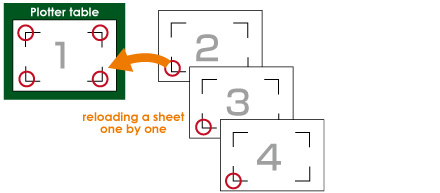

Multiple copies by reloading a sheet

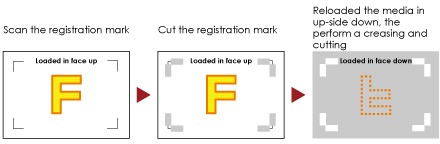

Reverse side Cutting/Creasing using ARMS

Cutting and creasing of printed graphics is possible even on the reverse side of the media. This prevents any scratches or damage to the printed graphic. On the FCX2000 Series, operation is simple using Cutting Master 4 or Graphtec Pro Studio.

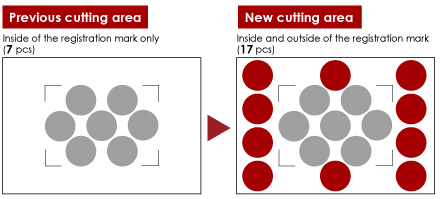

Expanded cutting area

This function expands the cutting area to include objects outside of the area enclosed by registration marks. Production efficiency is enhanced by reducing media waste.

Supported by standard crop marks

P&C is performed by printing the industry standard crop marks. Adding special marks with Graphtec software is not necessary. Operation is simple when crop mark information is entered within Cutting Master 4 software.

Reversed color registration mark

Marks are detectable when there is reasonable contrast against the background. For example, a white mark on a colored background.

When the reversed style mark is used, it is able to detect even on the media such as the type of glossy or shiny.

Tools and Equipments

Provided tools suitable for many applications

The FCX2000 series has 2 tool holder in the carriage.

Using 2 different kind of tool allows to do a different job

without exchanging a tool at the same time. it can increase work efficiency.

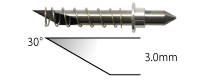

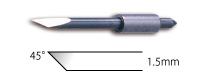

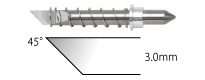

Cutting blade

A variety of the cutting blade in the line-up for different applications

For vinyl media

(CB09UB)

For Sand-blast rubber

(CB15U-K20)

For Rigid media, soft plastic or rubber

(PM-CB-001)

For vinyl media

(CB09UB-K60-5)

For High intensity reflective film

(CB15UA)

For thick media

(CB15U)

For High intensity reflective film

(CB15UA-K30)

For thicker media or small character

(CB15U-K30)

For Rigid media, Corrugated board

(CB30UC)

Creasing tool

Added to the current 3 different type of the creasing tool, new creasing tool PM-CT-002 is now available. This new tool reduces peeling and cracking on the printed surface during the creasing/scoring process compared to our existing tools.

Pen type, for

curves on heavy paper

(PM-CT-002)

Stick type,

for heavy paper

(CP-001)

Roller type,

for cardboard

(CP-002)

Roller type,

for corrugated board

(CP-003)

Loupe for cutting blade (PM-CT-001)

The loupe is a standard accessory used to easily adjust extruded blade length with the PHP33/PHP35 blade holders.

Useful utility space

Storing supplies as the cutting blade, blade holder, adhesive tape or others.

Roll media stoker

Various roll type material can be mounted, besides of sheet type media.

Supported media width : up to 950 mm

Supported media weight : up to 5 kg

Enhancement of safety

Supports a dedicated stop switch for stopping the machine when emergency case is occurred.

Intuitive operation with 3.7-inch graphic type LCD

Settings can be easily set using the large 3.7-inch LCD (240 x 128 dots) and tactile control panel.

Software

Graphics design software

Graphtec Pro Studio / Graphtec Pro Studio Plus

Easy-to-use application software for creating original designs. It has enhanced functions such as auto-shapes, shading, and editing functions. It can also configure the cutting conditions and other settings on the plotter. Importing of EPS, Ai, CMX, and PDF file types are supported. Graphics created with other popular design software can be imported into the software.

Easy-to-use application software for creating original designs. It has enhanced functions such as auto-shapes, shading, and editing functions. It can also configure the cutting conditions and other settings on the plotter. Importing of EPS, Ai, CMX, and PDF file types are supported. Graphics created with other popular design software can be imported into the software.

Supported OS : Windows 10/8.1/8/7

Design software for Mac OS

Graphtec Studio

This is an easy-to-use application software for Mac OS to create original designs.

This is an easy-to-use application software for Mac OS to create original designs.

Images can be easily created by using the program icons that are arranged around the drawing area.

Supported OS : Mac OS X 10.6 to 10.11 / macOS 10.12 (Sierra)

plug-in software

Cutting Master 4

Cutting Master 4 is Graphtec plug-in software for Adobe Illustrator and CorelDRAW Graphics Suite. It sends cut data to the plotter and includes a variety of functions such as: preview, registration mark creation, tool conditions, cut job settings and more. Cutting Master 4 is easy to use and enables you to get the best performance from your plotter.

Cutting Master 4 is Graphtec plug-in software for Adobe Illustrator and CorelDRAW Graphics Suite. It sends cut data to the plotter and includes a variety of functions such as: preview, registration mark creation, tool conditions, cut job settings and more. Cutting Master 4 is easy to use and enables you to get the best performance from your plotter.

Supported OS : Windows 10/8.1/8/ 7、Mac OS X 10.7 to 10.11 / macOS 10.12 (Sierra)

Supported software Illustrator :

CC2017/CC2015.3/CC2015/CC2014/CC/CS6/CS5/CS4 (Supporting CS4 is the only Windows OS),

CorelDRAW Graphics Suite 2017/X8/X7/X6/X5/X4

Specifications

Specifications

| Model name | FCX2000-60VC | FCX2000-120VC | FCX2000-180VC | FCX2000-120ES (*1) | |

|---|---|---|---|---|---|

| Configuration | Digital servo system, Flatbed | ||||

| Media hold-down method | Vacuum suction | Electrostatic | |||

| Effective cutting area | 610mm x 920mm | 1,200mm x 920mm | 1,800mm x 920mm | 1,200mm x 920mm | |

| Mountable media (Y-axis) | 950mm | ||||

| Roll media support | Roll media stocker (manual feeding), supported media; width: up to 950 mm, weight: up to 5 kg | ||||

| Maximum cutting speed | 400 mm/s (1 to 40 cm/s in 16 steps), in all directions | ||||

| Cutting force | Tool 1: Max. 4.9 N (500 gf), Tool 2: Max. 9.8 N (1 kgf) | ||||

| Cutting force settings | Tool 1: in 40 steps, Tool 2: in 40 steps | ||||

| Minimum character size | Approx. 10 mm square (varies with character font and media) | ||||

| Programmable resolution | GP-GL mode: 0.1/0.05/0.025/0.01 mm, HP-GL™ : 0.025 mm | ||||

| Distance accuracy | Max. 0.1% of the distance moved or 0.1 mm, whichever is larger (in plotting mode) (*2) | ||||

| Perpendicularity | Max 0.5 mm / 900 mm (in plotting mode) | ||||

| Repeatability | Max 0.1 mm (excluding contraction of media, in plotting/cutting mode) (*2) | ||||

| Standard interfaces | RS-232C, USB2.0 (High-Speed), and Ethernet (10BASE-T/100BASE-TX) | ||||

| Buffer memory | 2MB | ||||

| Command sets | GP-GL and HP-GL™ emulation (set by menu, or selects automatically by received data) | ||||

| Number of tools | Two tools | ||||

| Cutting blade, pen, and tool types | Cutting blade (supersteel), Pens (Water-based fiber-tip pen, oil-based ballpoint pen), and Creasing/scoring tool | ||||

| Others | ARMS, Reverse side Cutting/Creasing using ARMS, ARMS Copy function, Creasing, Cutting/creasing in multiple passes | ||||

| Power source | 100 to 240 VAC, 50/60 Hz (Auto switching) | ||||

| Power consumption | Max. 140 VA | ||||

| Operating environment | Temperature: +10 to +35 ºC, Humidity: 35 to 75% RH (non-condensing) | ||||

| Guaranteed accuracy environment | Temperature: +16 to +32 ºC, Humidity: 35% to 70% RH (non-condensing) | ||||

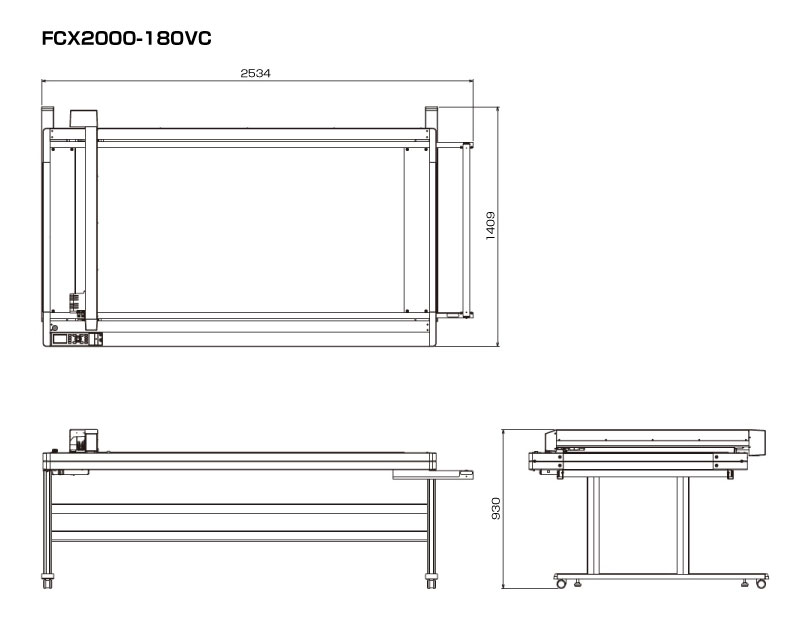

| External dimensions [W x D x H] (Approx.) |

1344 x 1409 x 930 mm (Including stand) |

1934 x 1409 x 930 mm (Including stand) |

2534 x 1409 x 930 mm (Including stand) |

1934 x 1409 x 930 mm (Including stand) |

|

| Weight (Approx.) | 76 kg (Including stand) (*3) | 99 kg (Including stand) (*3) | 116 kg (Including stand) (*3) | 93 kg (Including stand) | |

| Compatible OS (*4) | Windows 10 / 8.1 / 8 / 7, Mac OS X 10.7 to 10.11 / macOS 10.12 | ||||

| Supported software (*4) (*5) | Cutting Master 4, Graphtec Pro Studio, Graphtec Studio(for Mac) | ||||

| Compatible Standards |

Safety | UL60950-1/cUL, CE marking (Low voltage and EMC) | |||

| EMC | FCC-A, EN55032-A | ||||

- *1

- Available in a limited region. Please contact your local representative of Graphtec.

- *2

- When operated with Graphtec specified media and conditions.

- *3

- Pump (blower) for vacuum suction media hold-down system is not included.

- *4

- For more information about Windows and Macintosh compatibility, please check the website or contact your local representative of Graphtec.

- *5

- The software can be used by downloading from Graphtec website.

Media type

| Type of media | Thickness | Support cutting blade | FCX2000-60VC | FCX2000-120VC | FCX2000-180VC | FCX2000-120ES |

|---|---|---|---|---|---|---|

| Self-adhesive marking film (vinyl, fluorescent, reflective) |

up to 0.25 mm | CB09UB | 〇 | 〇 | 〇 | 〇 |

| Heavy paper/board (pattern paper, oil board) |

up to 0.5 mm | CB15U, CB15U-K30 | 〇 | 〇 | 〇 | 〇 |

| up to 1.0 mm | CB30UC | 〇 | 〇 | 〇 | 〇 | |

| Compressed foam sheet | up to 0.8 mm | CB15U-K30 | 〇 | 〇 | 〇 | - |

| Sandblast resist rubber | up to 1.0 mm | CB15U-K20 | 〇 | 〇 | 〇 | 〇 |

| Cardboard (F/G flute) | up to 1.1 mm | CB30UC | 〇 | 〇 | 〇 | 〇 |

| CB15U-K30 | 〇 | 〇 | 〇 | 〇 | ||

| Clear sheet for plastic boxes | up to 0.5 mm | CB15U | 〇 | 〇 | 〇 | 〇 |

| up to 1.0 mm | CB15U-K30 | 〇 | 〇 | 〇 | - | |

| High-intensity reflective film | up to 0.5 mm | CB15UA | 〇 | 〇 | 〇 | - |

| up to 1.0 mm | CB15UA-K30 | 〇 | 〇 | 〇 | - |

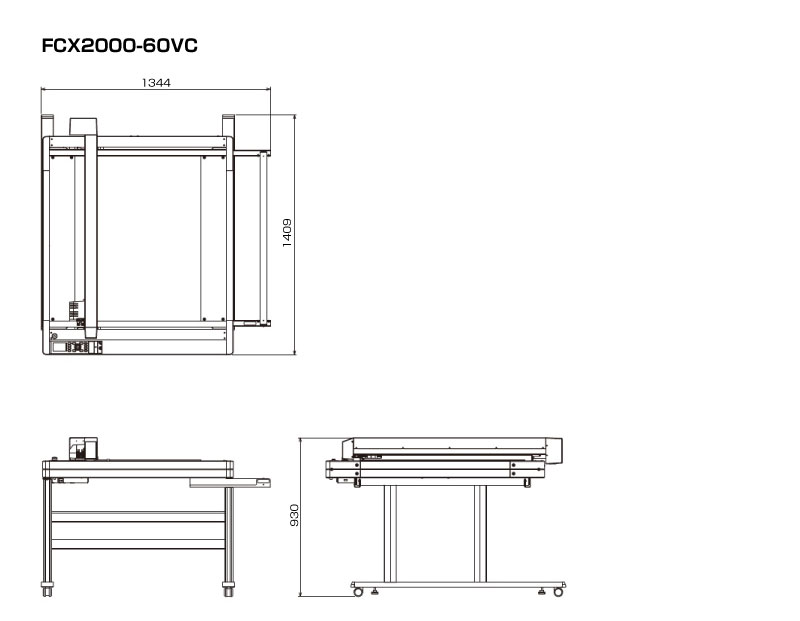

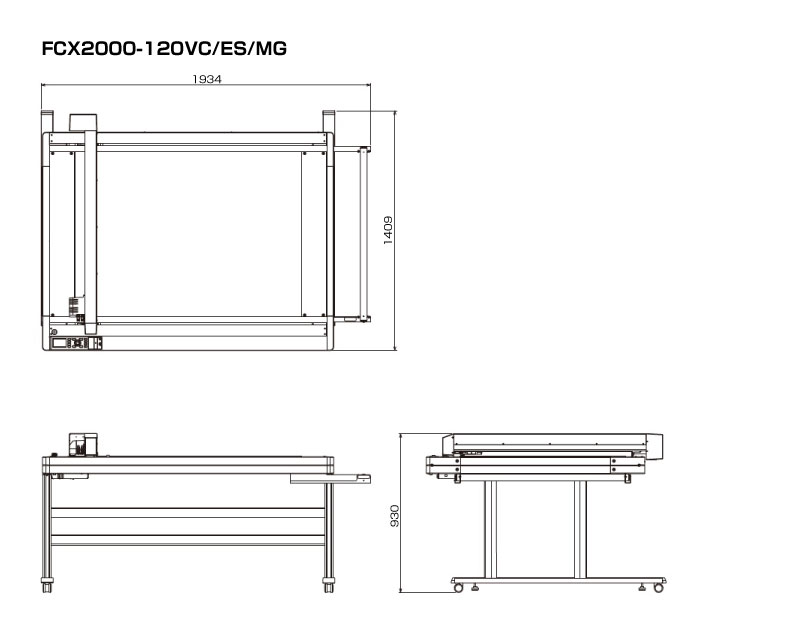

Dimensions

Scale : mm

Tolerance : +/- 5 mm

Scale : mm

Tolerance : +/- 5 mm

Scale : mm

Tolerance : +/- 5 mm

Accessory

Standard Accessory

| item | Q'ty | Description |

|---|---|---|

| Power cable | 1 pc. | The type of cable is different by destination |

| Cutting blade holder | 1 set | PHP35-CB15-HS |

| Cutting blade | 1 set | CB15U (2 blades), CB15U-K30 (5 blades) |

| Loupe | 1 pc. | PM-CT-001, for checking blade length |

| Fiber-tip pen | 1 set | KF700-BK (Black) and PHP31-FIBER (pen holder) |

| Height adjustment tool | 1 set | For adjusting position of tool head (plate, key wrench) |

| USB cable | 1 pc. | Length 2.9 m |

| Roll media stocker | 1 set | Loadable media: width up to 950 mm, weight up to 5 kg |

| Stand | 1 set | Legs of the stand (Connecting bar is packed with main unit) |

| DVD-ROM | 1 pc. | User's manual, Windows driver |

| Printed document | 1 set | Quick guide, Safety manual |

| Durable flexible hose | 1 pc. | For VC models only, 1.5 to 5 m (shrinked/extended) Connection bore diameter: 50mm |

| Hose band | 2 pcs. | For VC models only, to fix the hose |

Support

Please visit Graphtec Website to update latest information and software versions

http://www.graphtec.co.jp/en/imaging/fcx2000/support.html