|

|||||||||||||||||||||

|

PRE-TREATMENT |

|||||||||||||||||||||

|

|

|||||||||||||||||||||

|

|||||||||||||||||||||

|

|||||||||||||||||||||

|

|||||||||||||||||||||

| KEY FEATURES | |||||||||||||||||||||

|

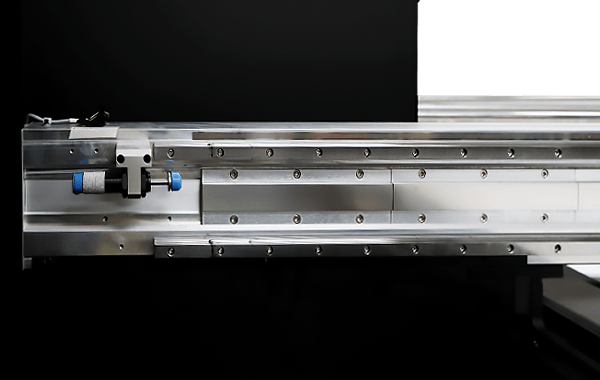

LINEAR MOTOR AND METAL ENCODER SCALE The linear motor and metal encoder scale ensure high-precision printing, while also maintaining low operational and maintenance costs. |

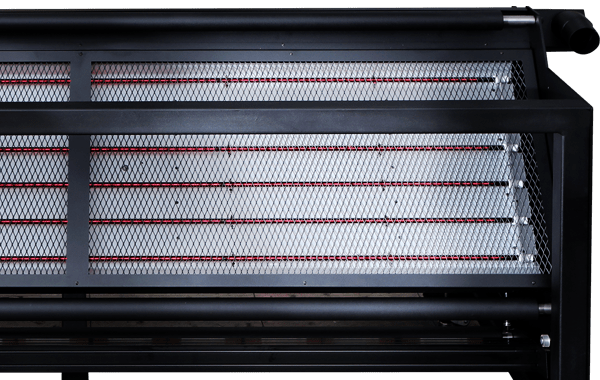

POWERFUL IN-LINE DRYER The In-line dryer is equipped with six infrared lamps, making it more powerful and explicitly designed to efficiently dry even the thickest fabrics at high speeds. |

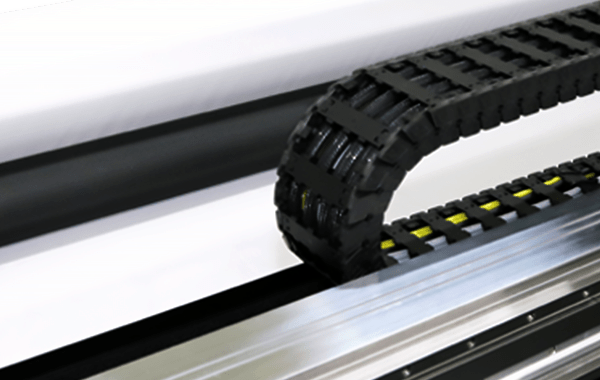

HIGHLY VERSATILE FABRIC FEEDING SYSTEM The feeding system provides edge positioning control to ensure perfect feeding. Additionally, it incorporates a pneumatic clutch to prevent distortion of the media. |

|||||||||||||||||||

|

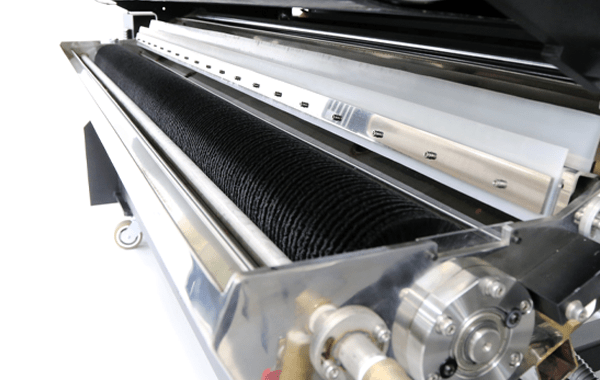

ADVANCED BELT WASHING UNIT Equipped with a powerful brush and dryer, the advanced belt washing unit enhances the long- lasting tackiness of the glue. |

UPGRADED DEGASSING SYSTEM The degassing system improves runability for continuous printing, reduces cleaning time, prevents missing nozzles, and minimizes excessive ink usage. |

SMART FABRIC PRESS ROLLER The smart fabric press roller finely regulates |

|||||||||||||||||||

| SPECIFICATIONS | ||||||

| Printing | Ink | Printing Speed | ||||

|

Print Head Ricoh, 10 Heads

Ink Type Pigment

Number of Colour 6 + CBS

Max Printing resolution 600 x 1200 dpi

Max Printing width 1830mm

Printing Mode - Bi-Direction - Uni-Direction |

Pigment Cyan, Mangenta, Yellow, Black + Lc, Lm, Or, Bl, Sc, Gr

Ink Capacity 5L

|

600 X 600dpi 2pass 117m2/h

600 X 900dpi 3pass 86m2/h

600 X 1,200dpi 4pass 65m2/h

|

||||

| Meida (Roll) | Operational Environment | Others | ||||

|

Max Media Width 1880mm

Core Diameter Feeder 320mm, 2~3inch

Media Drive Adhesive Belt Conveyor System

Belt Washing Automatic

MaxMedia Load Diameter : 320mm, Weight : 40kg Diameter : 320mm, Weight : 100kg *Option (Rubber Band Shaft)

MaxMedia Thickness 2mm |

Temperature 22oC ~ 25oC

Humidity 45 ~ 65% * Environmental influences canaffect print quality.

|

Rip SoftwareP Ergosoft, Caldera, Wasatch

Dimensions Printing Machine: 4130(W) x 1700(D) x 1800(H) mm Dryer (6heats): 2475(W) x 625(D) x 750(H) mm

Weight Printing Machine: 2800kg Dryer (6heats): 1470kg

Electricity Printing Machine: 9.82kW, 3Φ AC 380~415V, 14.92A Dryer (6heats): 7.85kW, 3Φ AC 380~415V, 11.91A

|

||||

|

OUR GLOBAL NETWORK DGI has been expanding its presence to approximately 80 countries. As last year, the service was being operated in various countries, including Italy, the UK, Saudi Arabia, and the US. Now, more than 3,600 companies are estimated to have been using it. The DGI fabric printer is equipped with an advanced infrared drying system, a stable fabric feeding mechanism, and a built-in belt washing unit to ensure continuous operation and consistent print quality. As the official DGI distributor in Vietnam, Golden Light provides a complete digital textile printing solution — including professional consultation, installation, operator training, and advanced color management. This helps businesses expand production capacity and enhance brand value in the professional textile printing industry.

|

|

|||||