Main

Digital Label Creation System

LCX1000 Series

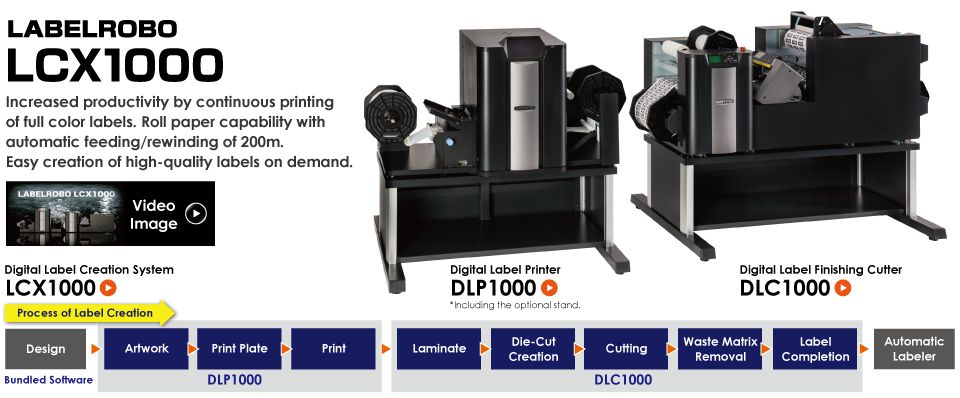

LABELROBO LCX1000 is a full-fledged digital label creation system developed with the concept of "Easy creation of high-quality labels on demand".The system consists of two products. The "DLP1000" is a high speed and high durability electrophotographic digital label printer.And the "DLC1000" is a digital label finisher with the functions of laminating, free size and shape cutting, waste matrix removal, slitting, and rewinding.

Equipped with Large Capacity HDD

Capable of Controlling Print Without the Use of a PC

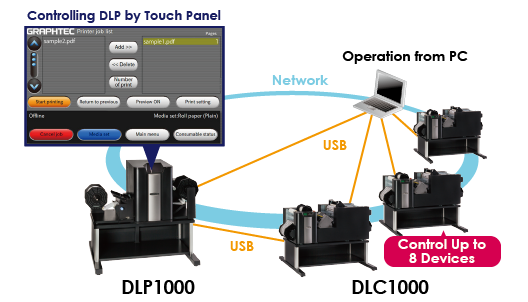

Not only can it be controlled by PC, the LCX1000 can be controlled by the DLP1000 touch panel. Operate the finishing cutter through the print/cut data cited in the large capacity server of the DLP1000 through its touch panel. The system enables smooth work transition between label printing and the finishing processes.

Controls Up to 8 DLCs Through a Single DLP Device

Not only can it be controlled by PC, the LCX1000 system can control up to 8 DLC1000 devices through the DLP1000 touch panel. Insert printed roll paper into the DLC1000, and transmit cut data from the DLP1000. It Improves work efficiency.

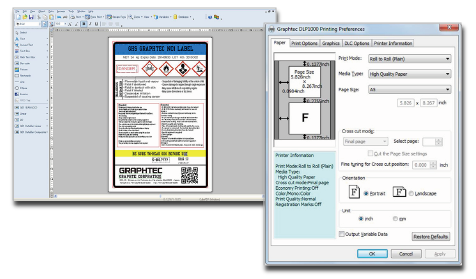

Comes standard with Label Creation Software

Label creation software is included. Creating label is able to start immediately after this system is installed.

High quality color label including the GHS label is able to be easily created. It is able to easily control the label finisher and printer using the Windows driver.

It can be used in a way to fit with the environment of use.

Features

- Creates the label design

- Imports an image data to label

- Corresponds to the variable data as serial number

- Supports barcode creation

DLP1000

Digital Label Printer DLP1000

Main Features

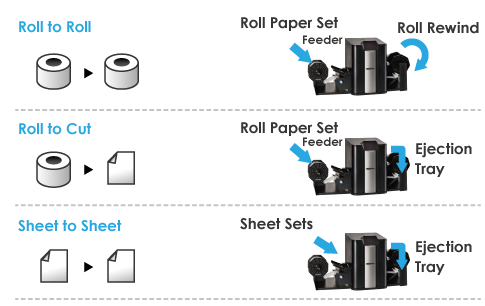

- Roll paper capability; 3 WAY feeding system

- Maximum printing width of 6 inches (152.4 mm)

- High resolution printing of 600 x 2400 dpi

- High speed output at 124mm / s

- Improve production by centrally controlling up to 8 DLCs

- Diversify uses with a variety of specialized substrates

- Accompanied by specialized label creation software

Centrally Control Print and Cut Operations Through Touch Panel

Manage inputted print data through touch panel.Controls the settings of print and reprint without the use of a PC, and also controls the DLC1000.

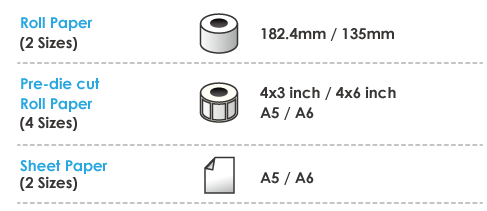

3 WAY Feeding System

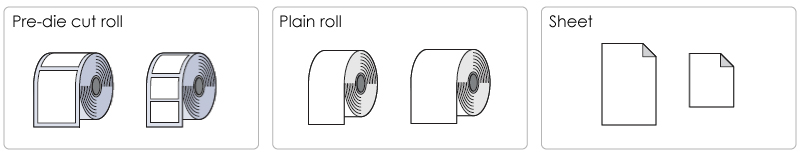

Capable of using roll or sheet paper through the 3-way feeding system to suit the printing amount and various other purposes.

Handle a Variety of Specialized Substrates

Achieved weather and light-resistant finish with 3 types of substrates in 8 Sizes.Possibility of diverse uses; flexible compatibility with auto-labeling and finishing processes.

Substrate Capability

High Quality Paper / Glossy Paper /

Synthetic Paper / PET Film White /

DLC1000

Digital Label Finishing Cutter DLC1000

Main Features

- Perform all the label creation processes by one device

- Roll-to-roll capability for continuous finishing process

- Equipped with the cutter enabling free-form cutting

- Laminating for weather resistant finish

- Sheet feeding by cross-cutting

- Slitting function capability

- Improved label processing efficiency with barcode reference

- Handles max web width of 216 mm

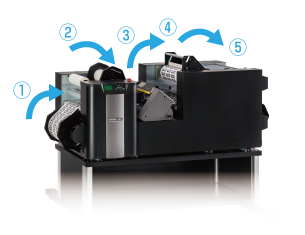

Roll-to-Roll Capability for Continuous Finishing Process

Easy finishing with DLC1000 by setting printed roll paper as is. Continuous flow with DLP1000 enables reduction in process errors and improvement in work efficiency.

Capable of Free-Form Cutting

Equipped with finishing cutter system developed with Graphtec’s own cutting technology. Capable of cutting in any shapes and sizes without the dies for cutting. Lowers total label production cost.

Reduce Process Errors by Referencing Barcodes

Verifies consistency with barcode and cut data before label finishing. An alert message will be displayed for any inconsistencies. Prevents finishing process errors.

Specification

DLP1000 Digital Label Printer Specification

| Item | Specification | ||

|---|---|---|---|

| Printinbg method | Electrophotographic 4 colors tandem + Intermediate Transfer | ||

| Photoconductor | OPC drum (+) | ||

| Developing method | Non-magnetic contact developing | ||

| Fusing method | Heat roller pressing | ||

| Resolution | Main scanning direction: 600 dpi Sub scanning direction: 2400 dpi, 1200 dpi, 600 dpi |

||

| First print time | 40 sec. or less, when A5 size of one paper (portrait) is printed | ||

| Warm-up time | Approx. 6mins (including calibrations) | ||

| Print speed | 124 mm/sec. monochrome or color in 600, 1200 dpi 62 mm/sec. color in 2400 dpi |

||

| Substrate type (Label with backing sheet) | High Quality Paper, Polyester-based Synthetic Paper, PET Film White, Glossy Paper, Semi Gloss Paper |

||

| Paper size | Paper width: 100 mm to 182.4 mm (6 inches + 30 mm) Paper length: 279.4 mm (11 inches) to 1 roll (Roll paper) Max. print length per 1 page: 1200 mm (47.24 inches) |

||

| Roll paper | Maximum diameter: 10 inches (254 mm) | ||

| Paper core inner diameter: 3 inches (76.2 mm) | |||

| Printing surface: front face | |||

| Paper width: Roll paper 182.4 mm (6 inches + 30 mm) 131.6 mm (4 inches + 30 mm) 178 mm (A5 width + 30 mm) 135 mm (A6 width + 30 mm) |

|||

| Paper width: Roll paper (Pre-die cut) 182.4 mm (6 inches + 30 mm) 131.6 mm (4 inches + 30 mm) 178 mm (A5 width + 30 mm) 135 mm (A6 width + 30 mm) |

|||

| Cut paper | A5 (148 mm x 210 mm) A6 (105 mm x 148 mm) |

||

| Paper thickness | 136 μm to 166 μm (including backing sheet) | ||

| Print margin | Roll paper; Leading edge: 3 mm, Trailing edge: 3 mm Left edge: 2 mm, Right edge: 2 mm Roll paper; (Pre-die cut) Leading edge: 2 mm, Trailing edge: 2 mm Left edge: 2 mm, Right edge: 2 mm Cut paper; Leading edge: 3 mm, Trailing edge: 3 mm Left edge: 2 mm, Right edge: 2 mm |

||

| Paper feeding method | Roll paper: Supported by the unwinder unit Cut paper: Supported by the sheet feeder unit (Max. loading capacity 20 sht.) |

||

| Paper ejection method | Selectable 3-way Roll to Roll, Roll to Cut, Sheet to Sheet |

||

| Roll Paper cut method | Cut cross (compatible with auto loading) | ||

| Toner supplying method | Toner cartridge replacement | ||

| Interface | USB2.0 (High Speed): PC connection USB2.0 (High Speed): DLC1000 connection Network (Ethernet 10BASE-T, 100BASE-TX, 1000BASE-T) |

||

| Control panel | 7-inch color LCD touch panel display | ||

| HDD capacity | 500 GB | ||

| OS Supported | Windouws Vista / 7 / 8 / 8.1 /10 (32/64 bit) | ||

| Power supply | US: 120 V AC, 60 Hz EU: 230 V AC, 50 Hz |

||

| Maximum power consumption | US: 1680 W or less EU: 1610 W or less |

||

| Operational noise | • Standby: 59 dB (A) or less • Operating: 74 dB (A) or less • Unexpected: 81 dB (A) or less |

||

| Usage environment | 15 to 32 ºC, 15 to 85 % R.H. (non-condensing) | ||

| Condition for guaranteed precision | 15 to 27 ºC, 30 to 70 % R.H. (non-condensing) | ||

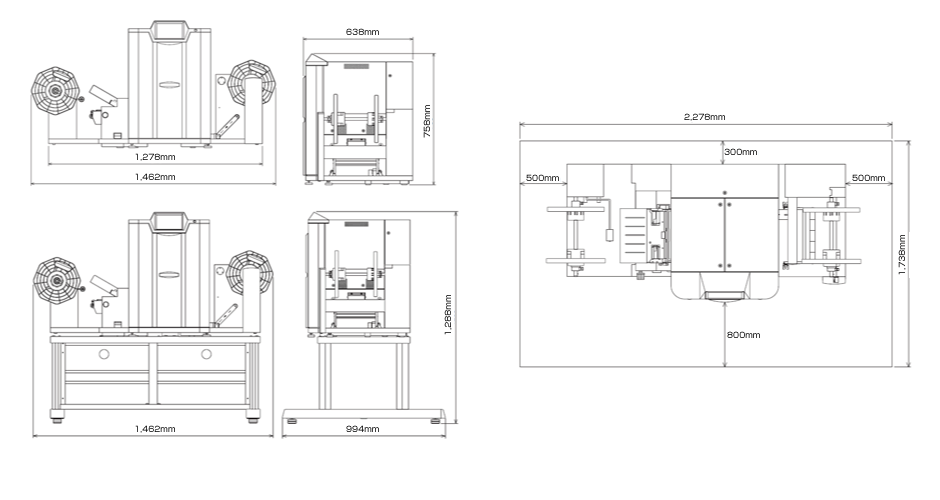

| Externam dimensions (approx.) | 1462 (W) x 638 (D) x 758 (H) mm | ||

| Weight (approx.) | 110 kg | ||

*The appearance, rating, specifications of the product are subject to change without notice for product improvement, etc.

DLC1000 Digital Label Finishing Cutter Specification

| Item | Descriptions | ||

|---|---|---|---|

| Paper feed unit | Loadable width | Maximum 216 mm Minimum 100 mm |

|

| Page length | Maximum 1200 mm (*1) | ||

| 1-page size: Maximum 300 mm, Minimum 76.2 mm | |||

| Loadable roll substrate | Maximum 254 mm (10 inches) Maximum weight 10 kg or less Paper core inner diameter 76 mm (3-inch paper core) |

||

| Laminate Section | Loadable width | Maximum 196 mm Minimum 80 mm |

|

| Loadable roll media | Maximum 200 m, or up to outer diameter 210 mm Maximum weight 8 kb or less Paper core inner diameter 76 mm (3-inch paper core) |

||

| Windable roll media | Maximum outer diameter 200 mm Paper core inner diameter 25.4 mm (1-inch paper vore) Paper core length 227 mm |

||

| Separator Section | Windable roll media (*2) | Maximum outer diameter 200 mm, or 200 m roll media paper can be wound up Paper core inner diameter 25.4 mm (1-inch paper core) Paper core length 227 mm |

|

| Winding Section 1 | Loadable width | Maximum 216 mm Minimum 55 mm |

|

| Windable roll media (*2) | Maximum outer diameter 254 mm, or 200 m roll paper can be wound up Maximum weight 14 kg or less Paper core inner diameter 76 mm (3-inch paper core) |

||

| Winding Section 2 | Loadable width | Maximum 108 mm Minimum 55 mm |

|

| Windable roll media (*2) | Maximum outer diameter 220 mm, or 200 m roll media paper can be wound up Maximum weight 7 kg or less Paper core inner diameter 76 mm (3-inch paper core) |

||

| Sliter Section | 3 locations | ||

| Cross Cut Section | Cut | Cross Cut | |

| Cutting Section | Cutout system | Half cut using blade (Supersteel) | |

| Cutter type | Supersteel | ||

| Drive system | Digital servo | ||

| Force | 0.2 to 2.9 N (20 to 300 gf): 31 steps | ||

| Maximum cut area | Expand Mode: 203 mm x 1200 mm (Slitter cannot be used.) Normal Mode: 186 mm x 1200 mm |

||

| Maximum cut speed | 600 mm/s | ||

| Main Unit Specifications | Interface | USB2.0 (High Speed), Network (Ethernet 10BASE-T/100BASE-TX) | |

| LCD display | Graphic Type (128 dots × 64 dots): 21 (characters) x 7 | ||

| Rated power supply | 100 to 120 V AC, 200 to 240 V AC, 50/60 Hz (Automatic changeover) | ||

| Power consumption | 170 VA or less | ||

| Usage environment | 10 to 35 ºC, 35 to 70 % R.H. (non-condensing) | ||

| Conditions for guaranteed precision | 16 to 32 ºC, 35 to 70 % R.H. (non-condensing) | ||

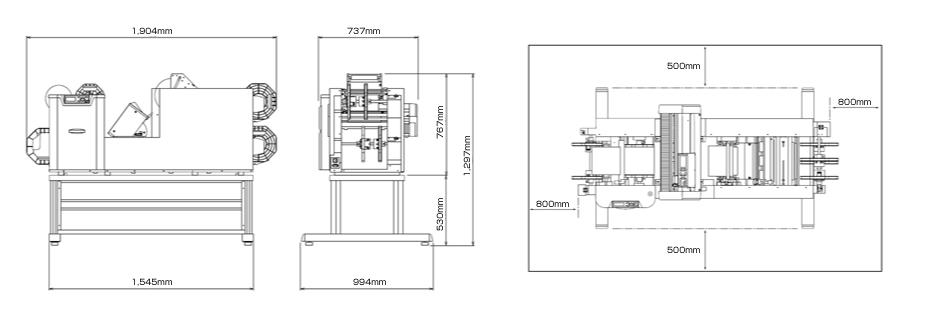

| External dimensions (approx.) | 1904 (W) × 994 (H) × 1297 (D) mm | ||

| Weight (approx.) | 151 kg | ||

- *1

- When setting substrate for long-plotting.

- *2

- It depends on Graphtec-specified conditions.

- *

- The external appearance, rating, specifications, etc., of product are subject to change without notice for product improvements, etc.

-

Consumable Item

Substrate

| High Quality Paper | Roll, Pre-die cut 4 x 3" (101.6 x 76.2 mm), 3000 labels | DLP‐1066R‐43‐HQP‐R1 | 1 roll / pack | |

| Roll, Pre-die cut 6 x 4" (152.4 x 101.6 mm), 2500 labels | DLP‐1574R‐64‐HQP‐R1 | 1 roll / pack | ||

| Roll, Pre-die cut A5 (148 x 210 mm), 1150 labels | DLP‐1530R‐A5‐HQP‐R1 | 1 roll / pack | ||

| Roll, Pre-die cut A6 (105 x 148 mm), 1750 labels | DLP‐1110R‐A6‐HQP‐R1 | 1 roll / pack | ||

| Roll, Plain, 5.31" x 656.17' (135 mm x 200 m) | DLP‐1350R‐HQP‐R1 | 1 roll / pack | ||

| Roll, Plain, 7" x 656.17' (178 mm x 200 m) | DLP‐1780R‐HQP‐R1 | 1 roll / pack | ||

| Roll, Plain, 7.18" x 656.17' (182.4 mm x 200 m) | DLP‐1824R‐HQP‐R1 | 1 roll / pack | ||

| Sheet, A5 (148 x 210 mm), 250 sheets | DLP‐A5S‐HQP‐S1 | 250 sheets / pack | ||

| Sheet, A6 (105 x 148 mm), 500 sheets | DLP‐A6S‐HQP‐S1 | 500 sheets / pack | ||

| Glossy Paper | Roll, Pre-die cut 101.6 x 76.2 mm, 2400 labels | DLP‐1066R‐43‐GP‐R1 | 1 roll / pack | |

| Roll, Pre-die cut 152.4 x 101.6 mm, 1840 labels | DLP‐1574R‐64‐GP‐R1 | 1 roll / pack | ||

| Roll, Pre-die cut 152.4 x 203.2 mm, 920 labels | DLP‐1574R‐68‐GP‐R1 | 1 roll / pack | ||

| Roll, Pre-die cut 148 x 210 mm, 920 labels | DLP‐1530R‐A5‐GP‐R1 | 1 roll / pack | ||

| Roll, Pre-die cut A6 (105 x 148 mm), 1200 labels | DLP‐1110R‐A6‐GP‐R1 | 1 roll / pack | ||

| Roll, Plain, 135 mm x 200 m | DLP‐1350R‐GP‐R1 | 1 roll / pack | ||

| Roll, Plain, 182.4 mm x 200 m | DLP‐1824R‐GP‐R1 | 1 roll / pack | ||

| Semi Gloss Paper | Roll, Plain, 135 mm x 200 m | PZ-PR-020 | 1 roll / pack | |

| Roll, Plain, 182.4 mm x 200 m | PZ-PR-018 | 1 roll / pack | ||

| Polyester-based synthetic paper | Roll, Plain, 135 mm x 200 m | DLP‐1350R‐PBW‐R1 | 1 roll / pack | |

| Roll, Plain, 182.4 mm x 200 m | DLP‐1824R‐PBW‐R1 | 1 roll / pack | ||

| PET film | Roll, Plain, White, 135 mm x 200 m | DLP‐1350R‐PW‐R1 | 1 roll / pack | |

| Roll, Plain, White, 182.4 mm x 200 m | DLP‐1824R‐PW‐R1 | 1 roll / pack | ||

Winding Core

| Type | Description | Model number | Package | |

| Paper core for spool of winding | For DLP1000 and DLC1000 | Inner diameter: 3 inches, width: 106.5 mm | DLP‐1065R‐3CORE‐R5 | 5 pcs / pack |

| Inner diameter: 3 inches, width: 111.0 mm | DLP‐1110R‐3CORE‐R5 | 5 pcs / pack | ||

| Inner diameter: 3 inches, width: 135.0 mm | DLP‐1350R‐3CORE‐R5 | 5 pcs / pack | ||

| Inner diameter: 3 inches, width: 153.0 mm | DLP‐1530R‐3CORE‐R5 | 5 pcs / pack | ||

| Inner diameter: 3 inches, width: 157.5 mm | DLP‐1575R‐3CORE‐R5 | 5 pcs / pack | ||

| Inner diameter: 3 inches, width: 178.0 mm | DLP‐1780R‐3CORE‐R5 | 5 pcs / pack | ||

| Inner diameter: 3 inches, width: 182.5 mm | DLP‐1825R‐3CORE‐R5 | 5 pcs / pack | ||

| For DLC1000 | Inner diameter: 3 inches, width: 79.0 mm | DLC‐790R‐3CORE‐R5 | 5 pcs / pack | |

| Inner diameter: 1 inch, width: 227.0 mm | DLC‐2270R‐1CORE‐R5 | 5 pcs / pack | ||

Toner, Imaging Cartridge

| Type | Description | Model number | Package | |

| Toner Cartrdge | Cyan, with one wast toner bottle | DLP‐T1000‐C | 1 set / pack | |

| Magenta, with one wast toner bottle | DLP‐T1000‐M | 1 set / pack | ||

| Yellow, with one wast toner bottle | DLP‐T1000‐Y | 1 set / pack | ||

| Black, with one wast toner bottle | DLP‐T1000‐K | 1 set / pack | ||

| Inaging Cartridge | Cyan, with one wast toner bottle | DLP‐D1000‐C | 1 set / pack | |

| Magenta, with one wast toner bottle | DLP‐D1000‐M | 1 set / pack | ||

| Yellow, with one wast toner bottle | DLP‐D1000‐Y | 1 set / pack | ||

| Black, with one wast toner bottle | DLP‐D1000‐K | 1 set / pack | ||

| Waste toner box | Waste toner box | DLP-W1000 | 1 pc / pack | |

Laminate film

| Type | Description | Model number | Package | |

| Laminate Film | Polypropylene film, Clear, 115 mm x 200 m | DLC‐1150R‐PP‐R1 | 1 roll / pack | |

| Polypropylene film, Clear, 158 mm x 200 m | DLC‐1580R‐PP‐R1 | 1 roll / pack | ||

| Polypropylene film, Clear, 162 mm x 200 m | DLC‐1620R‐PP‐R1 | 1 roll / pack | ||

| PET film, Clear, 115 mm x 200 m | DLC‐1150R‐PET‐R1 | 1 roll / pack | ||

| PET film, Clear, 158 mm x 200 m | DLC‐1580R‐PET‐R1 | 1 roll / pack | ||

| PET film, Clear, 162 mm x 200 m | DLC‐1620R‐PET‐R1 | 1 roll / pack | ||

Consumable for DLC1000 & Options for DLC1000/DLP1000

| Type | Description | Model number | Package | |

| Consumable for DLC1000 | Cutter blade, 0.9 mm dia. | CB09UB‐5 | 5 blades / pack | |

| Cutter blade holder for CB09 blade | PHP33-CB09N-HS | 1 set / pack | ||

| Cutting mat | CE6-CM40-2 | 2 pcs / pack | ||

| Options | DLP & DLC | Roll holder (Flange set for supplying) | OPH-A28 | 1 set / pack |

| DLC1000 | Roll holder (Flange set for winding) | OPH-A29 | 1 set / pack | |

| DLC1000 | Boxes for separated debris | OPH-A31 | 1 set / pack | |

| DLP1000 | Stand for DLP1000 | ST0105 | 1 set / pack | |

Recommended initial supply kit

| Type | Description | Model number | Q'ty | |

| DLP1000-RIS-KIT | Toner Cartridge Cyan with waste toner bottle | DLP-T1000-C | 1 set | |

| Toner Cartridge Magenta with waste toner bottle | DLP-T1000-M | 1 set | ||

| Toner Cartridge Yellow with waste toner bottle | DLP-T1000-Y | 1 set | ||

| Toner Cartridge Black with waste toner bottle | DLP-T1000-K | 1 set | ||

| High Quality Paper, Roll, Plain, 182.4 mm x 200 m | DLP-1824R-HQP-R1 | 1 roll | ||

| Winding core, Inner diameter: 3 inches, width: 182.5 mm | DLP-1825R-3CORE-R5 | 5 pcs | ||

| DLC1000-RIS-KIT | Laminate Film, PP, Clear, 111 mm x 200 m | DLC‐1110R‐PP‐R1 | 1 roll | |

| Winding core, Inner diameter: 1 inch, width: 227.0 mm | DLC‐2270R‐1CORE‐R5 | 5 pcs | ||

| Winding core, Inner diameter: 3 inches, width: 53.5 mm | DLC‐535R‐3CORE‐R5 | 5 pcs | ||

| Winding core, Inner diameter: 3 inches, width: 79 mm | DLC‐790R‐3CORE‐R5 | 5 pcs | ||

| Roll holder (Flange set for supplying) | OPH-A28 | 1 set | ||

| Roll holder (Flange set for winding) | OPH-A29 | 1 set | ||