HIGH SPEED SUBLIMATION PRINTER

OVERVIEW

High-Speed Sublimation Printer

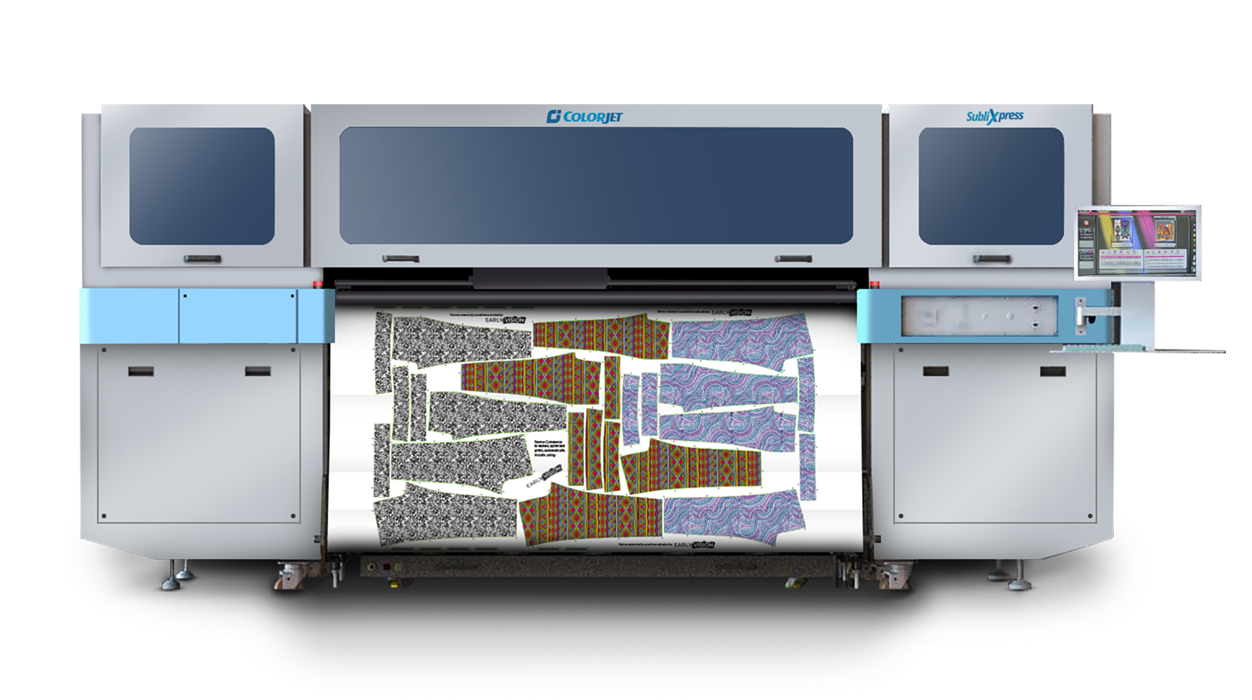

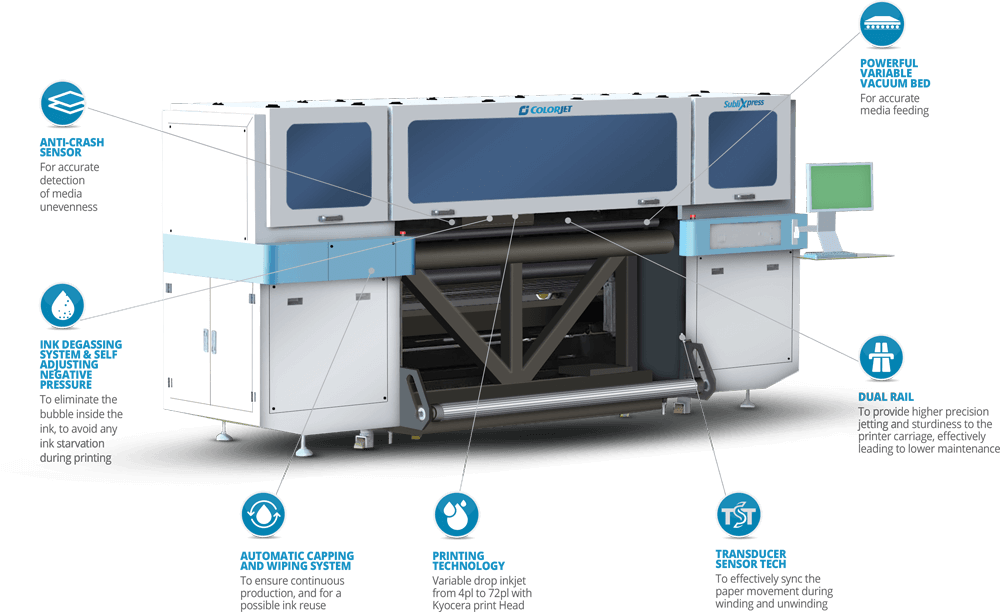

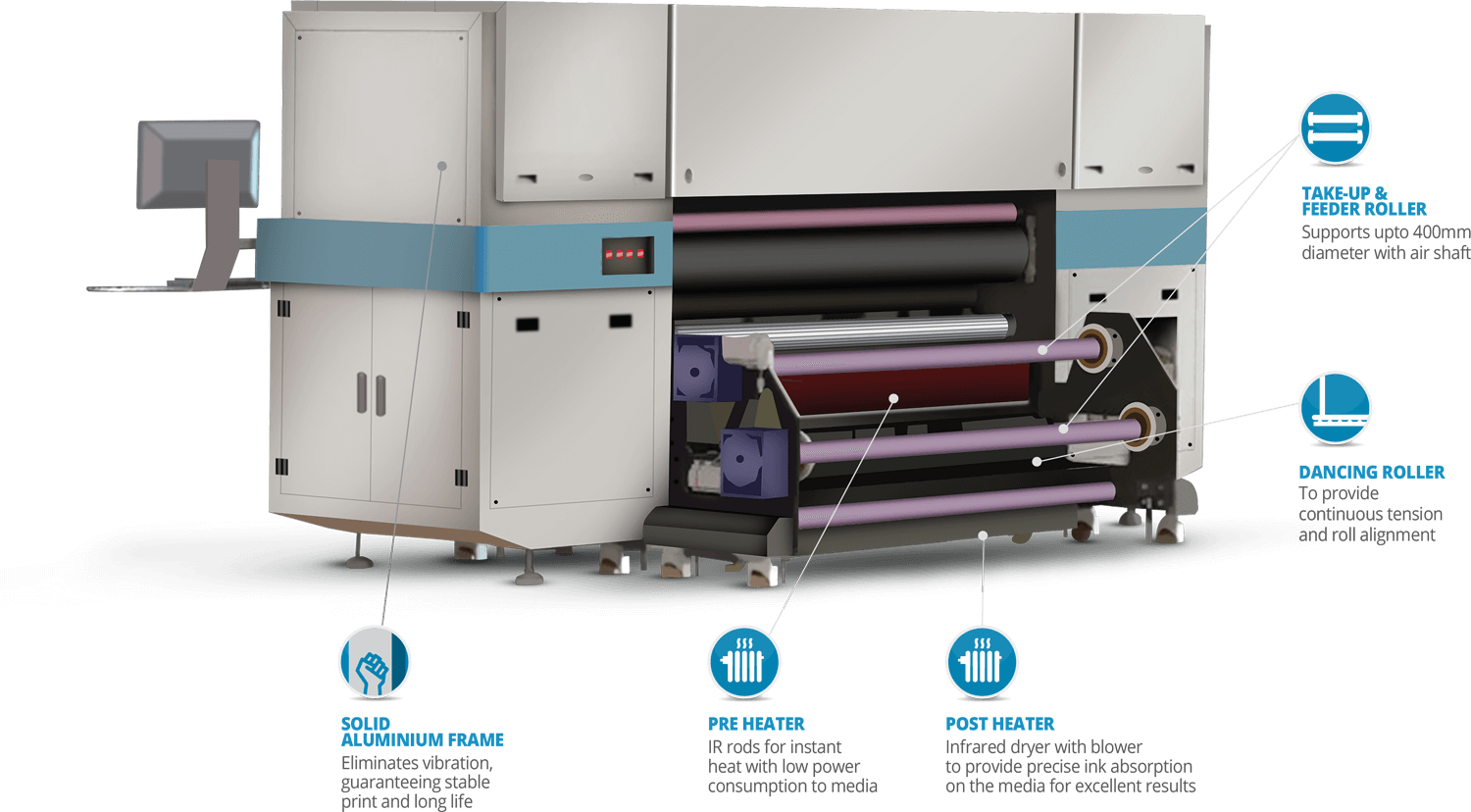

SubliXpress is a high-speed sublimation machine and a game-changer in the business of industrial sublimation printing machine. This dye-sublimation printer is India's fastest ROI 1.6 m sublimation machine. Equipped with up to 4 industrial-quality Kyocera print-heads, it prints variable ink-jetting intensities between 4-72 PL. The polyester fabric printing machine offers the capacity of 4000 sq. m/day. It enables the textile print businesses to obtain high volume output with a single high-speed sublimation machine. Its industrial feed and take-up system supports diameter roll of up to 400 mm. This sublimation paper transfer machine comes with an advanced ink degassing system to eliminate any kind of bubbles inside the ink giving the print a smooth finish. Low power consumption is one of the advantages of the dye-sublimation printer making it an eco-friendly polyester fabric printing machine. SubliXpress, the high-grade industrial sublimation printing machine comes with infrared dryers for instant drying. This high-speed sublimation machine comes preloaded with advanced Colorjet edition of the RIP software with colour management engine and colour processing tools. It offers fabric specific ICC profile for smooth gradations and vibrant colours for superior print quality.

PRIME BUSINESS REASONS TO BUY

INDIA'S FASTEST ROI SUBLIMATION PRINTER

Up to 4Kyocera Head

Up to 4Kyocera Head

Multiple Drying System

Multiple Drying System

AST - Active Seaming Technology

AST - Active Seaming Technology

Super Powerful Vacuum bed

Super Powerful Vacuum bed

TST - Transducer Sensor Tech for low GSM paper handling

TST - Transducer Sensor Tech for low GSM paper handling

Industrial Feeding & Take-up Roller with Airshaft

Industrial Feeding & Take-up Roller with Airshaft

FEATURES

|

|

|

|

SPECIFICATION

SubliXpress works on the technology of Drop-on-demand, Piezoelectric Inkjet that prints up to the high quality of 600x2400 DPI with the option of 4 colours and upto 4 print heads. It is a high-speed sublimation machine with speed going up to 210 sq. meters per hour. It offers the convenience of varied file formats including JPEG, TIFF, BMP, PDF (RGB/CMYK). Dye sublimation aqueous based inks are used in the refillable ink system of SubliXpress. ColorJet edition of Onyx, RIP software is supported.

SubliXpress |

|||||

|

Models

|

X4406

|

X4203

|

|||

| Printing Technology |

Drop-on-demand, Piezo Electric Inkjet

|

||||

| No. of Print Heads |

4

|

2

|

|||

| Print Heads | Type |

Industrial Grade Jetting Assemblies

|

|||

| Resolution |

Upto 2400 dpi

|

||||

| Height Adjustment |

Upto 20mm

|

||||

| Cleaning Method |

Pressure Purge and Wiping

|

||||

| Wetting Control |

Piezoelectric actuations

|

||||

| Inks | Types |

Dye Sublimation Aqueous based Inks

|

|||

| No. of Color |

4

|

4

|

|||

| Supply |

Refillable

|

||||

| Media | Max. Thickness |

Upto 20 mm

|

|||

| Max/Printing Width |

Upto 1650 mm

|

||||

| Roll Daimeter |

400 mm

|

||||

| Distance Accuracy |

Error of less than +0.3 % of distance travelled, or +0.3 mm, whichever is greater

|

||||

| Media Drying System |

Infrared Heaters

|

||||

| Printing Interface |

USB 3.1

|

||||

| Rip Software Supported |

Onyx(ColorJet Edition)

|

||||

| File Format |

JPEG/TIFF/BMP/PDF (RGB/CMYK)

|

||||

| Power Requirements(Print Engine) |

AC 220 V, 43 A, 50/60 Hz

|

||||

| Power Requirements(Dryer) |

AC 220 V, 20 A, 50/60 Hz

|

||||

| Dimensions (Printer Only) |

3775 x 1600 x 1830 mm

|

||||

| Dimensions (With Packing) |

3875 x 1470 x 2100 mm, 4180 x 880 x 1340 mm

|

||||

| Weight |

N.W.1450 Kg, G.W.1600 Kg

|

||||

| Operating Conditions |

Temperature: 20 to 28℃ Humidity: 50 to 65%RH (non-condensing)

|

||||

| Speed(In Sq.Meter/Hr) |

Print DPI

|

Passes

|

X4406

|

X4203

|

|

| Mode 1 |

600 x 600

|

1

|

210

|

-

|

|

| Mode 2 |

600x1200

|

2

|

123

|

-

|

|

| Mode 3 |

600x1800

|

3

|

88

|

-

|

|

| Mode 4 |

600x2400

|

4

|

68

|

-

|

|

| Mode 5 |

600x300

|

1

|

-

|

182

|

|

| Mode 6 |

600x600

|

2

|

-

|

128

|

|

| Mode 7 |

600x900

|

3

|

-

|

81

|

|

| Mode 8 |

600x1200

|

4

|

-

|

61

|

|

APPLICATIONS

SubliXpress is the go-to sublimation printing machine for a variety of applications. This polyester fabric printing machine also prints on most other types of fabrics. Apart from being used as a sports apparel printing machine, this sublimation paper transfer machine is also used for various other applications like, fashion apparels, home furnishings, personalised merchandise, sports gear, etc.

|

|

|

|

|

|

PRODUCT VIDEO

Product video will be uploaded soon...